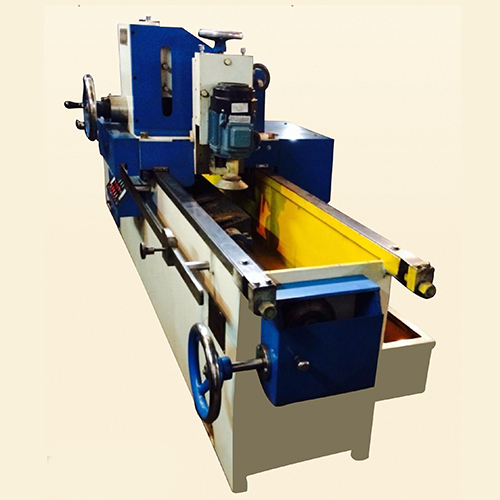

Our Automatic Surface Cum Edge Grinding Machine makes grinding jobs simpler and more precise. With dual functionality, this machine handles both surface and edge grinding effortlessly, so you don’t need multiple machines. Thanks to its automated design, it minimizes manual work while giving you a consistent, professional finish every time. Perfect for businesses looking to streamline their grinding processes and maintain high standards of quality.

Machine Bed

Welded, modular construction principle. Smooth inner area for good cooling water drainage and easy cleaning.

Guideways

Hardened and ground steel bands for main and side guides, easily exchangeable.

Electro Magnetic Table

Fixed for flat grinding with total table coverage, in Electro-Magnetic design.

Electro-Magnetic swivelling table for flat, bevel and multi surface grinding in one setting up operation, swivelling 360, multiple bearing points with large diameter journals for maximum rigidity. Additional clamping sides with 'T' slots & clamps (Optional). Electro Magnetic Table locking, by hand.

Grinding Head Carriage

Heavy casting mounting on four reels with eight New-Departure dust proof ball bearings which act as rollers. Four reels guide the carriage in the carriage ways of the bed. The sliding base, mounted on the top of the carriage, is adjustable to feed the grinding segmental or cup-wheel to the knife. The motor base can be swivelled 10 to 25. degrees, so that the knife can be ground eighter straight or concave as paper knives require only 5 degrees swivel of motor base.

Down-Feed for Grinding Tool

Multiple spindle system for play and weight equalisation

Automatic Down-Feed also available (Optional).

Grinding Motors

SIEMENS or BHARAT BIJLEE Brand.

Grinding Head

Cylindrical type bonded to flange for light grinders, segmental heads for heavy grinding machines.

For quick re-setting or changing of the segments, an easily accessible changing station is situated at the rear of the machine.

To ensure vibration-free running, all grinding wheel flanges and segmental heads are fitted with adjustable balancing weights. For obtaining maximum segment use, patented segment savers can be used.

Cooling System

Water tank attached with the machines. Cooling fluid application by the electro-coolant pump.

Electrical Unit

All electrical controls are housed in the master panel board.

| Models | Type | Grinding Capacity | Grinding Wheel Dia | Grinding Motors (H.P.) |

| PMS/60 EXPORT | (A) | 1550 * 200mm | 12 " | 7.5 H.P. & % H.P. |

| PMS/60 EXPORT | (B) | 1550 * 150mm | 20 " | 10 Η.Ρ. & % H.P. |

| PMS/72 EXPORT | (A) | 1850 x 200mm | 12 " | 7,5 H.P. & % H.P. |

| PMS/72 EXPORT | (B) | 1850 * 150mm | 20 " | 10 H.P. & % H.P. |

| PMS/84 EXPORT | (A) | 2150 * 150mm | 12 " | 10 H.P. & % H.P. |

| PMS/84 EXPORT | (B) | 2150 * 200mm | 14 " | 10 H.P. & % H.P. |

| PMS/84 EXPORT | (C) | 2150 * 250mm | 14 " | 15 H.P. & 2 H.P. |

| PMS/100 EXPORT | (A) | 2550 * 200mm | 12 " | 10 H.P. & 1 H.P. |

| PMS/100 EXPORT | (B) | 2550 x 250mm | 14 " | 15 Η.Ρ. & 2 H.P. |

| PMS/120 EXPORT | (A) | 3100 * 200mm | 12 " | 10 Η.Ρ. & 1 H.P. |

| PMS/120 EXPORT | (B) | 3100 * 2500mn | 14 " | 15 Η.Ρ. & 2 Η.Ρ. |

| PMS/120 EXPORT | (C) | 3100 * 300mm | 18" | 25 H.P. & 2 H.P. |

| PMS/156 EXPORT | (A) | 4000 * 200mm | 12 " | 10 H.P. & 1 H.P. |

| PMS/156 EXPORT | (B) | 4000 x 2500mm | 14 " | 15 Η.Ρ. & 2 H.P. |

| PMS/156 EXPORT | (C) | 4000 * 300mm | 18" | 25 H.P. & 2 H.P. |

| PMS/180 EXPORT | (A) | 4600 * 250mm | 14" | 20 H.P. & 3 H.P. |

| PMS/180 EXPORT | (B) | 4600 * 300mm | 18" | 25 H.P. & 3 H.P. |

| PMS/180 EXPORT | (C) | 4600 * 350mm | 20 " | 35 H.P. & 2 H.P. |

Grinding Machines Features:

| Type | Surface Cum Edge Grinding Machine |

| Body Material | MS Fabricated |

| Material Handling | Optional |

| Shape | Rectangle |

| Power Consumption | 5 KW To 15 KW |

| Dust Collection | Manual |

| Phase | Three Phase |

| Control System | Push Button Control |

| Grinding Wheel Type | Sigmental Head |

| Finish | Painted |

| Workpiece Size Capacity | Depends On Machine Model |

| Machine Power | SIEMENS Bharat Bijli Make |

| Table Movement | Surface Cum Edge |

| Maintenance Frequency | Almost Nil |

| Function | Precise Grinding Of Both Surface And Edge |

| Manufacture By | Indo Poly Machine Corporation |

| Country Of Origin | India |

Copyright © 2025 INDO POLY MACHINES CORPORATION All Rights Reserved.